En'Urga offers spray patternation (spray pattern) services at our laboratory. The SETScan optical patternator is used for nozzle testing. We offer testing of sprays with diameters up to 7 inches with our OP-600 model. For smaller sprays, we use the OP-200 patternator for better resolution. Many types of nozzles and injectors including high-pressure nozzles can be tested in our laboratory. From low flow pharmaceutical nozzles to high flow aerospace nozzles.

We can also custom fabricate fixtures for mounting your nozzles or injectors for patternation (spray pattern) tests. Additional requirements such as spraying frequency, nozzle pressure and spraying fluid can be accommodated.

Some information that can be obtained from patternation (spray pattern) testing is listed below:

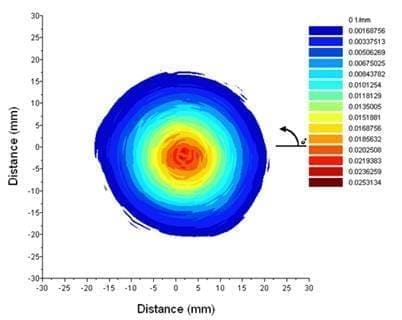

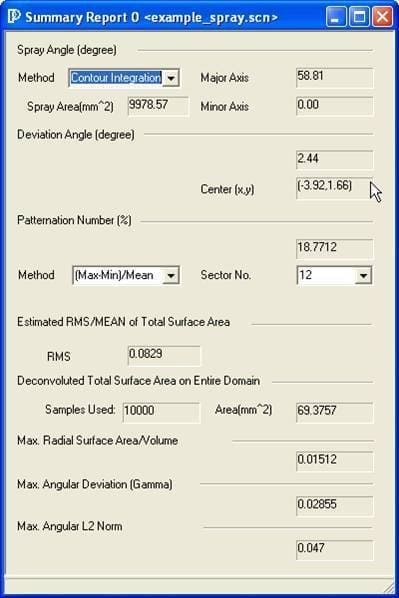

A contour plot and a summary report are shown below are two examples of the data provided during the contract testing of spray patternation (spray pattern).

Contour Map of spray cross section from SprayQC software of SETscan optical patternator

Summary Report provided by SprayQC software of SETscan optical patternator

Spray patternation (spray pattern) does not provide drop sizes. Drop Sizing is offered as a separate service. One of the main quantifications provided by optical patternation (spray pattern) is the Total Surface Area. This value represents the number of drops in the measurement domain multiplied by their surface areas. The units are surface area/unit volume or 1/mm.

To request more information about this service, please contact us using the Contact Form or by directly calling us.